The main difference between stainless steel elbow and carbon steel elbow lies in the material, and its chemical composition will cause long-term rust and corrosion on the surface of the elbow. In the pipeline system, elbow is an accessory to change the direction of the pipeline. According to the angle, there are three most commonly used: 45, 90 and 180. In addition, according to the engineering requirements, it also includes other elbows with abnormal angles, such as 60. In today's elbow industry, all kinds of industrial production are inseparable from pipeline connection, and the best tool for pipeline connection is flange. There are many kinds of common elbows in the market, which can fully meet our standardized production requirements and create convenient working and production conditions for us. At present, there are high-pressure flange, welded flange, etc. These two flanges need different working conditions and installation requirements. We must pay attention to the correct operation mode.

Stainless steel elbow connection requires gaskets, screws and nuts, which are necessary products for flange connection. When connecting pipes, the pressure requirements of high-pressure flange and low-pressure flange are different. We must select the product type through strict calculation and the industrial production requirements of our elbow. We absolutely need to weld the flange, which requires us to master professional and formal connection methods to reduce leakage and prolong the service life of the product.

In daily life, when we use 304 stainless steel elbow, it is generally only fully open or fully closed. At the same time, we will get rid of the rich cover and continue to accelerate wear and tear. Its material will be more convenient, the manufacture is very simple and the cost is particularly low. Will be widely used, but the rigidity is relatively poor. Therefore, it cannot be used for a series of processes and explosive objects. At the same time, there are a series of chemical processes and high system matching, which may endanger some occasions. Therefore, in the process of use, we must pay attention to comprehensive inspection.

As a kind of equipment that can effectively connect two pipes or pipe fittings together, stainless steel elbow flange has been basically required by some processing places. Of course, in the process of connection, first fix them on an elbow flange, and then add a cushion between the two pipe fittings and fix them together with bolts, so as to achieve the most effective connection. Of course, some housekeeper accessories have their own flanges. In this case, they also belong to the connection between flange and elbow.

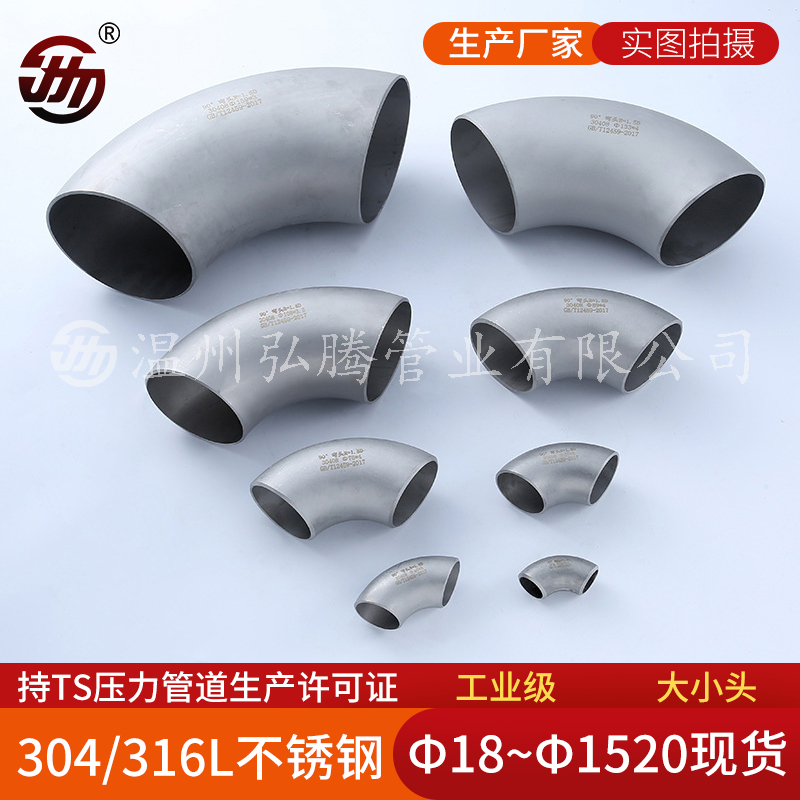

Stainless steel elbow is usually used to install water pipe. It is a pipe fitting connecting elbow and elbow. There are many kinds of stainless steel elbows, including 90 degree elbow, right angle elbow, stamping elbow, pressing elbow, mechanical elbow, welding elbow, etc.

Stainless steel elbow connects two pipes with nominal diameter or different diameters, and the pipes rotate 90, 45, 180 and various angles. Those with a bending radius less than 1.5 times the pipe diameter belong to elbows, and those with a bending radius greater than 1.5 times the pipe diameter belong to elbows.

Wenzhou Hote pipe fittings Co., Ltd

address:No.220 Fouth Street,Third Road,Binhai Industry Zone,Lonwan District,Wenzhou,Zhejiang China

email:hotepf@163.com

Mobile phone:13676586266

scan