For the manufacture of tee with seamless pipe, there are two commonly used processes: hydraulic bulging and hot pressing. The hydraulic bulging of stainless steel tee is a forming process of expanding the branch pipe through the axial compensation of metal materials. The process is to use a special hydraulic press to inject liquid into the pipe blank with the same diameter as the tee, and squeeze the pipe blank through the synchronous centering movement of the two horizontal side cylinders of the hydraulic press. The volume of the pipe blank becomes smaller after extrusion, and the liquid in the pipe blank increases with the volume of the pipe blank. When the pressure required for the expansion of the stainless steel tee branch pipe is reached, Under the dual action of the liquid pressure in the side cylinder and the tube blank, the metal material flows along the inner cavity of the die and expands out of the branch pipe.

Technical parameters:

1. Executive and reference standards: GB / T 12771-2000 stainless steel welded steel pipe for fluid transportation and GB / T 12459-2005 steel butt welded seamless pipe fittings.

2. Working temperature: - 40 ℃ ~ 200 ℃;

3. Corrosion resistance: the welds of pipe fittings are free of corrosion through salt spray test.

4. Flattening test: flatten the pipe fittings to 1 / 3 of the outer diameter without cracks or cracks;

5. Tensile strength: not less than 520mpa, elongation not less than 35%, the measured value of this product is 733 MPa;

6. Air pressure test: each pipe fitting has passed 1.6 MPa air pressure test;

7. Drawing test: the drawing force of socket argon arc welded pipe connection is 3 times of the national standard;

8. Pressure test: after connecting the pipe and pipe fitting, there is no leakage at the connection under the condition of 2.5 MPa and maintaining the pressure for 5min;

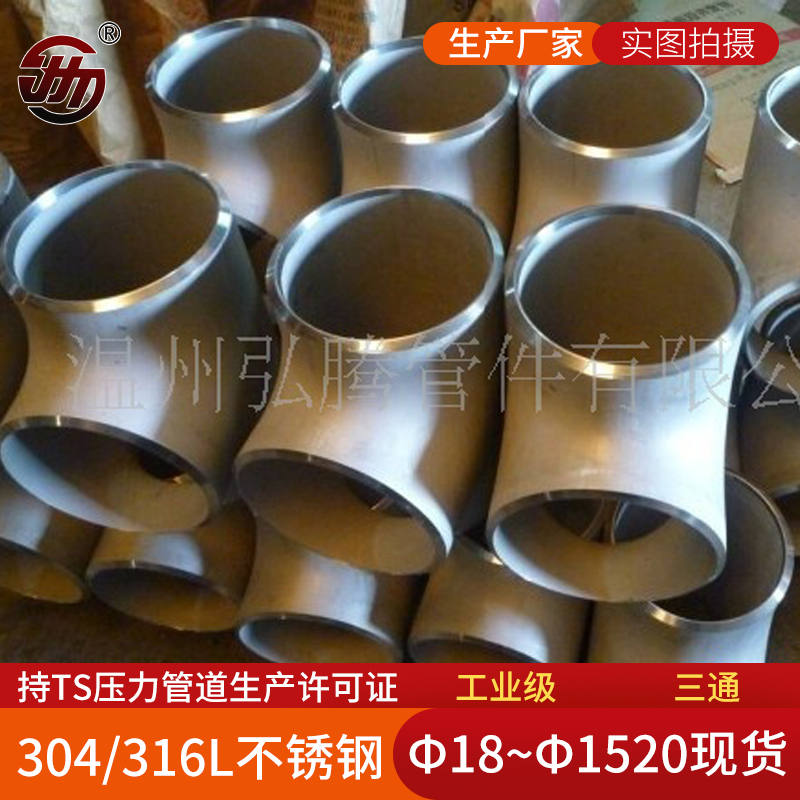

Stainless steel reducing tee

Special equipment for reducing tee pipe fittings: install ejector on the pipe, which includes metal rod, ejector, commutator, support, etc; Heat the metal rod, and when the jack and the metal rod are used to push out, the pipe wall material will turn out naturally to form the blank of reducing tee; Then, a certain length of pipe section with corresponding specifications is welded on the blank of reducing tee formed by ejection to produce the final product.

Technical parameters:

1. Working temperature: - 40 ℃ ~ 200 ℃;

2. Corrosion resistance: the welds of pipe fittings are free of corrosion through salt spray test.

3. Tensile strength: not less than 520mpa, elongation not less than 35%, the measured value of this product is 733 MPa;

4. Flattening test: flatten the pipe fittings to 1 / 3 of the outer diameter without cracks or cracks;

5. Executive and reference standards: GB / T 12771-2000 stainless steel welded steel pipe for fluid transportation and GB / T 12459-2005 steel butt welded seamless pipe fittings.

6. Pressure test: after connecting the pipe and pipe fitting, there is no leakage at the connection under the condition of 2.5 MPa and maintaining the pressure for 5min;

7. Drawing test: the drawing force of socket argon arc welded pipe connection is 3 times of the national standard;

8. Air pressure test: each pipe fitting has passed 1.6 MPa air pressure test;

The processing method of reducing tee is: mark the position where the reducing tee is to be processed and punch through the mark. The processing method of reducing tee fitting is suitable for the processing of reducing tee fitting on pipes of different specifications; The special processing equipment has the advantages of simple structure and low cost. The manufacturing of reducing tee pipe fittings does not need another injection molding machine and injection mold, which can reduce the production cost of such pipe fittings and improve the production efficiency.

Wenzhou Hote pipe fittings Co., Ltd

address:No.220 Fouth Street,Third Road,Binhai Industry Zone,Lonwan District,Wenzhou,Zhejiang China

email:hotepf@163.com

Mobile phone:13676586266

scan